Condition Monitoring and Forecasting of Subsea Hydraulic Systems Using Time Series Data

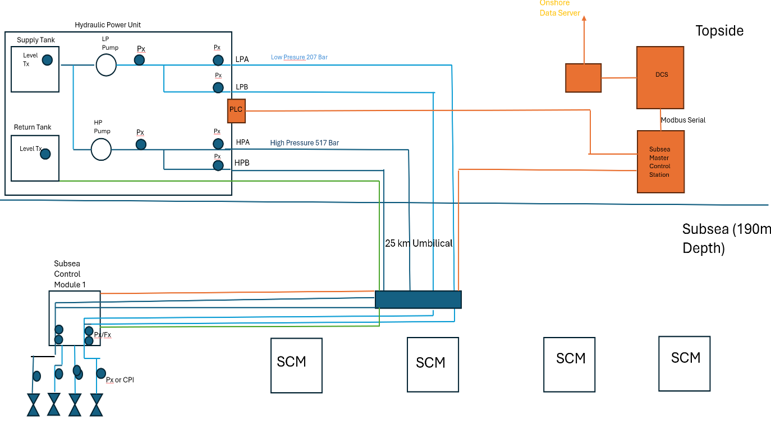

MSc Project to automate the monitoring of an Oil and Gas Subsea Production Hydraulic Control System. Anomalies/Failures result in production downtime, Subsea intervention and Environmental non-compliance reports.

Implement a machine learning based models to identify hydraulic fluid losses and abnormal system behaviour (high/low pressures, loss of redundancy, low tank levels, high return flow rates). Condition Monitoring / Anomaly Detection utilising Neural Network Machine Learning.

Monitor pump runtimes from the data to determine maintenance requirements. Predicitve Maintenance.

Predict future fluid consumption for environmental reporting and commercial purposes to ensure optimal quantities of hydraulic fluid is ordered. Time Series Demand Forecasting.

Calculate and display other useful data for operator such as daily/weekly/monthly fluid usage, umbilical charge volumes, high periods of valve ops, fluid added to tank, valve ops and expected fluid consumption. This may be by way of a Power BI dashboard to provide a single page with clear concise information. Data Manipulation and Visualisation.

Generate automated compliance-ready reports for submission to the regulatory authorities .Ensure KPIs such as fluid use, redundancy, pump runtime are clearly highlightred. Data Reporting

Use algorithms developed on static data for Real Time Data Monitoring. Deliver Real Life Value